LASER DIODE CURRENT OUTPUT

- Output Current Range: 0.00 - 120.00 Amps

- Compliance Voltage Range: 0.00 - 5.00 Volts

- Current Noise & Ripple (rms): < ± 0.5% of Full Scale Current

- Current Setpoint Resolution: 30 mA

- Current Setpoint Accuracy: ± 0.5%

- Current Stability (4 hours): ≤ 300 ppm

- Current Limit Setpoint Accuracy: ± 2%

- Photodiode Current Measurement Accuracy: ± 0.5%

- Photodiode Current Measurement Range: 0.00 - 700 μA

LASER DIODE PROTECTION FEATURES

- Soft-Start Current Ramp Factory Default Set to 300 Milliseconds; User Adjustable

- User-Programmable Current Limit

- Open Circuit Detection

- Short Circuit when Laser Diode Current Turned OFF

- ESD and Power Surge Clamp, AC Line Filter

- Reverse Voltage Transient Clamp

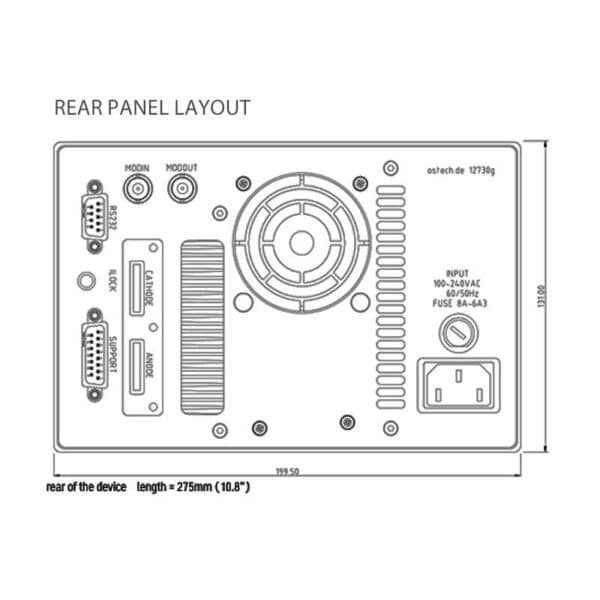

- Rear Panel Keylock Switch and Safety Interlock

- Front Panel e-Stop Button Emergency Shut-Down

QCW (QUASI-CW) MODE AND MODULATION

- Pulse Width Range < 25 μs to CW, 10%-90% (< 20 μs on request)

- Integrated Function Generator

- Pulse Time Base Accuracy: ± 1.0%

- QCW Mode Trigger: Internal (Integrated) Function Generator or External Trigger

- Modulation Input: BNC, Digital (TTL) or Analog, 10kΩ Impedance

- Modulation Input Voltage Range: 0 ~ 4 Volts (4V = Max Current)

- Analog Modulation Bandwidth: 1 Hz – 20 kHz

AUXILIARY FUNCTIONS AND CONNECTIONS

- Laser On/Off Status Indication (TTL; On = High), vs. Gnd

- Pilot Laser Output, vs. Gnd

- Photodiode Cathode, vs. Gnd

- External Cooling Fan Output (1 - 24 V, 800 mA), vs. Gnd

- External Temperature Sensor Input (NTC 10kΩ, vs. GND)

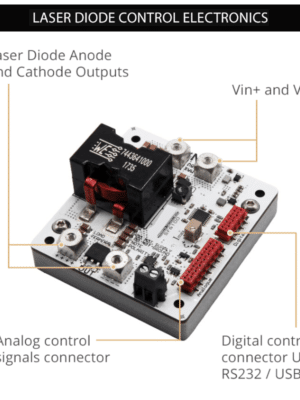

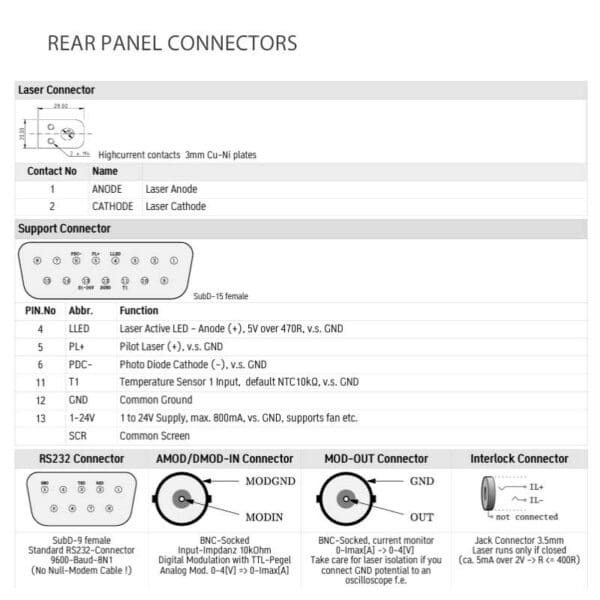

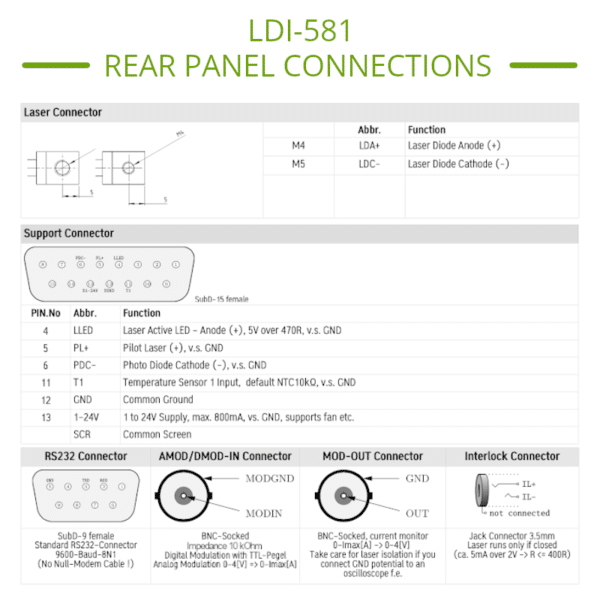

USER INTERFACE AND CONNECTORS

- Front Panel: Alphanumeric LCD with Key Pad

- RS232 Standard, SubD-9, Female

- Includes USB Adapter

- LabView Drivers Included

- Laser Diode Connector: Threaded Lugs for Bolt-On Leads

- Auxiliary Functions Connector: SubD-15 female

- RS232 Connector: SubD-9, Female / Includes USB Adapter

- Safety Interlock: Jack Connector, Stereo 3.5mm

DIMENSIONS AND POWER INPUT

- Power Input: Universal 100V ~ 240 VAC, 50/60 Hz

- Dimensions: 127 mm (H) x 200 mm (W) x 275mm (L)

RECOMMENDED ACCESSORIES

- kab-39 Unterminated Connecting Cable -or- kab-231 Terminated Connecting Cable

- acc-417 USB-RS232 Converter

High Power Laser Diode Driver | Current Range 120 Amps | Multi-Stage Protection Designed Specifically for High Power Laser Diodes

Key Features

- Multiple Layers of Laser Diode Protection:

- User Adjustable Current & Voltage Limits

- User Adjustable Soft-Start Current Ramp

- Protection Against Power Black-Out / Brown-Out & AC Surges

- Laser Diode Over-Temperature Shut-Down / External Monitor & Shut-Down - CW and QCW Modes | Integrated QCW Pulse Generator and Remote Trigger Input

- User Configurable Soft-Start Current Ramp and Enhanced High Power Laser Diode Protection Features

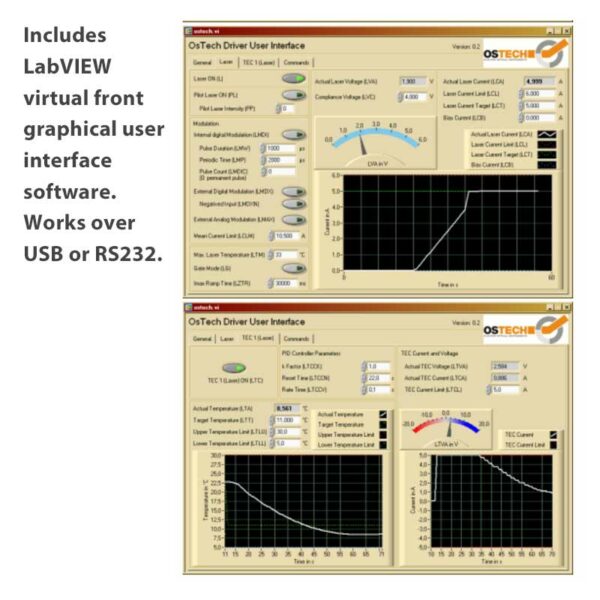

- RS232 Interface | Includes USB Adapter and LabView Drivers

Shipping Information

– Shipping rates in the USA: $75

– Please contact us for International Shipping Rates

Order Placement

Orders for this product in North America and select International Regions are processed and fulfilled by LaserDiodeControl.com, part of the Laser Lab Source Marketplace Group. This product is manufactured by Ostech, GmbH. Mfg Part Number: ls11-la120v05-t12782-v1-581

Warranty Information

This product is sold with a full one year warranty. It is warrantied to be free from defects in material and/or workmanship for a period of one year from the date of shipment. The warranty is transacted and honored by Laser Lab Source for product purchases made through Laser Lab Source.

|

Weight |

3 lbs |

|---|---|

|

Dimensions |

13 × 9 × 9 in |

|

Current Range |

25 Amps - 250 Amps |

|

Voltage Range |

1 Volt - 5 Volts |

|

Drive Current Mode |

CW + QCW Mode |

|

Form Factor |

Benchtop (front panel) |

|

Computer IO and Software |

GUI software included, RS-232 or 485, USB Available |

|

Driver Current |

120 A |

|

Driver Voltage |

5 V |

Product Overview

120 Amp High Power Laser Diode Driver for Bars, Stacks and Arrays

The LDI-581 laser diode driver provides up to 120 amps of current to bias high power laser bars and arrays. It operates in CW (constant current) or QCW (pulsed) mode. The drivers are designed specifically to safely bias fiber-coupled bar modules and CCP style copper mount devices from companies such as DILAS, Jenoptik, Coherent, Focuslight and Lasertel.

LDI-581 Laser Diode Driver

The LDI-581 has been designed to electrically bias high power laser diodes while protecting them from the common causes of damage which can harm or destroy the laser. Because high power lasers require relatively high levels of DC current and voltage, and generate high levels of waste heat, they have a unique set of electrical and thermal requirements which need to be addressed to protect them from being damaged. Additionally, the driver has been designed with features to assist the user to safely operate the laser diode under test. It offers features such as a front panel e-Stop power kill switch, redundant safety interlocks, and a front panel key-switch master power on/off.

Designed to Protect High Power Laser Diodes from Being Damaged

- User Adjustable Current and Voltage Limits

Setting current and voltage limits are necessary to ensure a long lifetime for the laser diode. Limits can be set using the front panel & key-pad, or through software and/ or Labview GUI. - User Adjustable Soft-Start Current Ramp

There is an internal 300 millisecond soft-start ramp to the current set-point. This reduces the potential for thermal shock to the laser at power ON and is used to ensure good electrical contact prior to fully applying the current bias the laser diode. The user has the ability to adjust the ramp time in order to optimize performance. These laser diode drivers offer the industries’ only user-set slow start current ramp to the bias set point. This allows the user to extend the ramp time out to 10’s of seconds to prevent the possibility of thermal shock and prevent over driving the module during the start up sequence. - Protection Against Power Black-Out / Brown-Out and AC Power Surges

AC line filters and power clamp circuitry protects the laser diode from AC input power

transients and surges. These transients can occur when the bench / wall power source is

momentarily interrupted due to a black or brown-out power outage. - Laser Diode Over-Temperature Shut-Down / External Monitor & Shut-Down

A thermistor input is provided to allow the user to monitor the temperature of the laser diode. This can then be used to shut the laser diode off if a temperature maximum for the laser diode is exceeded. Also included is the ability to control an external cooling fan. A temperature sensor input is available on the back panel, and the external fan control supply is capable of driving up to 500 mA at 24 V.

User Safety Features

The driver has been designed with features to assist the user to safely operate the laser diode under test. These features include a front panel e-Stop power kill switch, redundant safety interlocks, a front panel key-switch master power on/off, and an over-temperature thermistor sensor input.

CW and Quasi-CW Modes of Operation

In addition to CW (continuous wave) mode of operation, these laser diode drivers offer flexible modulation capabilities and an integrated QCW mode (integrated pulse generator). The user can apply a TTL digital or analog modulation input through the rear panel BNC. The controller has an internal function generator which can be used to set the modulation signal or the quasi-CW pulses with a time base accuracy of 1.0%. In QCW mode, the user can set pulse parameters from a remote TTL signal source or use the internal function generator.

User Interface / Front Panel + Keypad / RS232 / USB / LabVIEW Drivers

Controller setup is fast and intuitive via the front panel LCD display and keypad with a simple to use menu structure. These drivers come with standard an RS-232 interface and a USB interface adapter. The included LabView driver GUI makes set-up and control of the system fast and simple.