CURRENT, VOLTAGE & TEC CONTROLLER

- Output current LD (I): 0.00 - 3000.00 mА

- Output voltage range LD (V): 3 Volts

- Current stability: 0.1 %

- Current set accuracy: 1 %

- Output current noise: <15 µA

- ТЕС output current: ±4А

- TEC output voltage: ±4V

- TEC output current ripple: 2 - 4mА

- Temperature Control Range: +15 to +40 °C

LASER DIODE PROTECTION

- Current limit

- Temperature limit

- Reverse current protection

- ESD and transient protection

- Soft-start laser diode current ramp

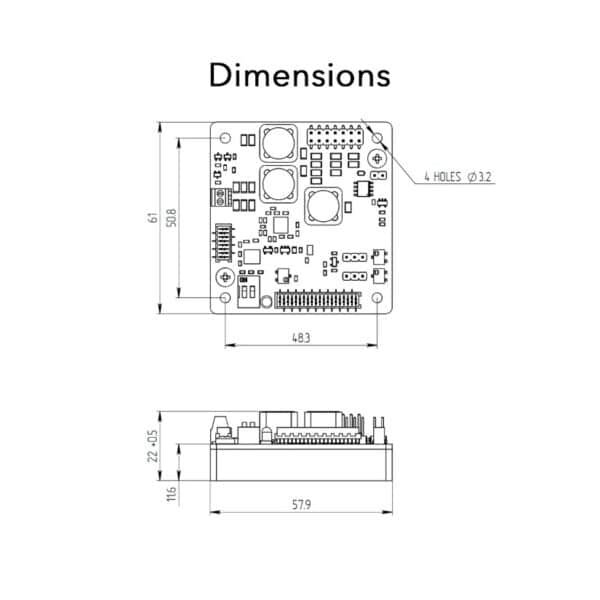

DIMENSIONS AND WEIGHT

- Dimensions 57.9 x 61 x 22 mm

- Weight: 115 g

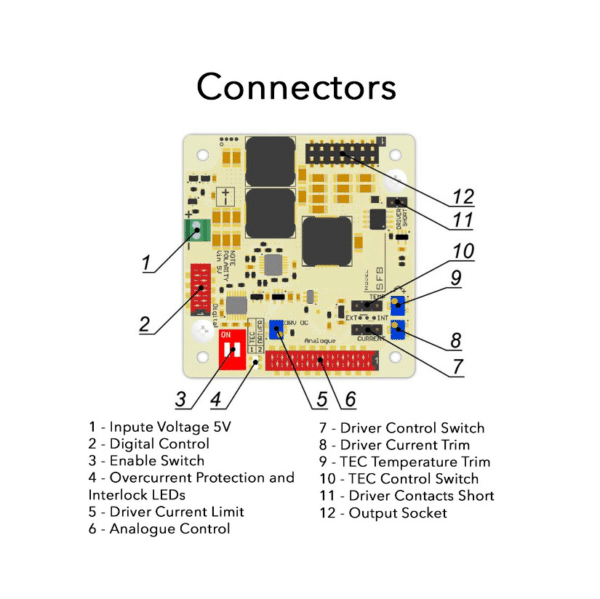

USER INTERFACE

- Trim Potentiometers for Driver Current and TEC Power

- Analog

- RS-232 / UART/ USB

INPUT

- Input voltage range (Vin): 5 V

- Recommended Linear / Switching Power Supply Options:

- Condor HC5-6-OV-A+G Linear Power Supply for better low-noise performance, narrow DFB laser line width

- Mean Well LRS-35-5, Switching Power Supply more economical; ideal for pump lasers

PACKAGE SET (Included Parts)

- Driver – 1 pcs

- 50 cm ribbon cable with one 8-pin connector – 1 pcs

- 50 cm ribbon cable with one 20-pin connector – 1 pcs

- Datasheet & User Manual – 1 pcs

WARRANTY PERIOD

- 1-Year Manufacturer's Warranty

OPTIONS AND ACCESSORIES

- USB Adapter: Part Number CL1 ~ price $35.00

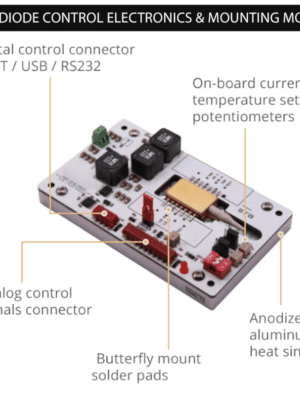

3 Amp LASER DIODE DRIVER / 16W TEC Controller Module

Key Features

- Hybrid Control & Mount Module:- 3000 mA Laser Diode Driver- 16W TEC Controller

- 4-LEVEL Advanced Laser Diode Protection:- Crowbar power surge & transient shunt- Soft-start current ramp- Current limit- Dual stage temperature limits

- User Interface Options:- On-board trimpots- Analog signal controls- RS232- USB (optional) w/ GUI interface software

Shipping Information

Shipping rates in the USA:

– All products: $25.00

– Please contact us for International Shipping Rates

Warranty Information

This product is sold with a full one year warranty. It is warrantied to be free from defects in material and/or workmanship for a period of one year from the date of shipment.

|

Weight |

1 lbs |

|---|---|

|

Dimensions |

10 × 8 × 6 in |

|

Current Range |

1 Amp - 5 Amp |

|

TEC Output Power (W) |

15 W |

|

Voltage Range |

1 Volt - 5 Volts |

|

Form Factor |

Board (no enclosure) |

|

Computer IO and Software |

GUI software included, RS-232 or 485, USB Available |

|

Driver Current |

3 A |

|

Driver Voltage |

3 V |

|

Maiman Model Number |

SF8025-NM |

Product Overview

Precision Laser Diode Current Source with TEC Controller / Compact Module

These low noise laser diode controller modules are designed to precisely bias and control the temperature of laser diodes. These controllers are an excellent choice for product integration or for laboratory test set-ups. Careful selection of components and and exacting design criteria allows the modules to provide complete control of your pump laser in a 61mm x 58mm package.

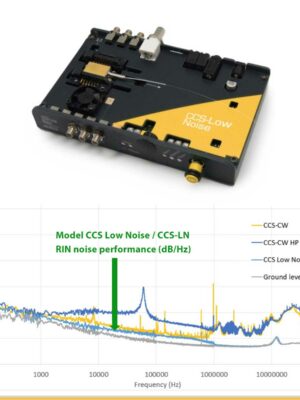

Flexible Control Interfaces and Control Software with GUI Included

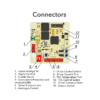

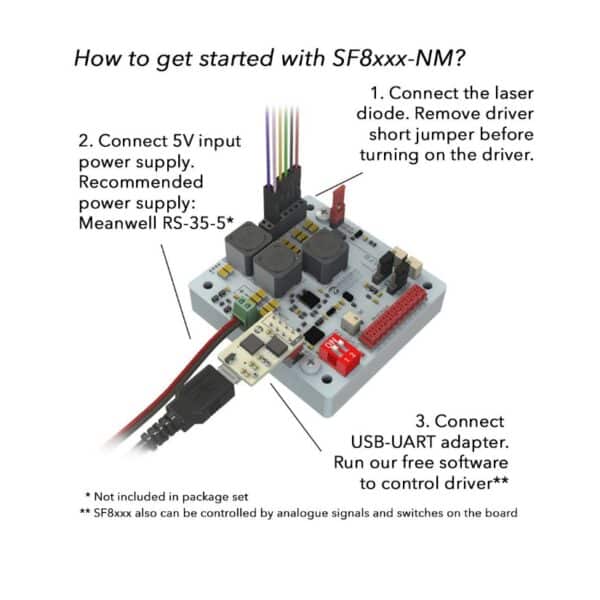

These controllers offers the user multiple interface methods to set and measure the modules parameters. For simple, fast start-up, the module has trim potentiometers which the user can access on top of the control board. This manual mode of control is typically used to make sure the driver is functioning properly prior to connecting the laser. For complete control of all parameters, the user has the choice of using an analog control signal connector or a digital interface. The 8 pin RS23 / UART digital interface and the 14 pin analog control connector are both described in detail in the attached brochure.

Sourcing Current to your Laser Diode and Crowbar Clamp Protection

The modules are initially enabled by applying an active high 3.3V ~ 5V DC compatible logic input signal. The driver sources current and begins to operate when the 5V input enable pin is high. To ensure that the current enable is applied without overshoot, a slow start sequence initiates when the enable pin is set high. The enable pin can also be used in the quasi-CW mode. The output current is set by applying an analog signal to the current set pin on the control connector. The current set pin can be used for analog modulation by applying sign wave, square wave or ramp signal. The output may be pulsed by applying a TTL square signal to enable pin. The minimum pulse duration 500 microseconds. These high power drivers offer a highly reliable crowbar clamp to quickly short the current and disable power to your laser diode in the event the current there is a surge from the power supply or an over-temperature condition. There is a pin on the control connector which shows the crowbar protection circuit status. The crowbar will short the output while the module is in an over-current shutdown or an over-temperature shutdown mode.

On-Board Component Level Protection Against Input Power Surges and Reverse Voltage Transients

An integrated on-board zener diode in parallel with the bias current path protects the laser diode from damage which can occur from reverse voltage transients. These transients can occur when a standard DC power supply source is momentarily interrupted due to a black-out or brown-out power outage.

User Adjustable Current and Temperature Limits

The user can set current limit and temperature limits through on-board potentiometers. Limits can also be set using your PC through the included control software. Finally, limits can be set using the analog control signals input. Setting limits are necessities to ensure a long life-time for your laser.

Soft-Start Current Ramp

There is an internal 500 millisecond soft-start ramp to the current set-point. This reduces the potential for thermal shock to the laser at power ON and is used to ensure good electrical contact prior to fully applying the current bias the laser diode.

Additional External Over-Temperature Monitor Input

Primarily designed for integration of the module into a laser system, an additional thermistor input is

provided to allow the user to monitor the temperature from an external measurement point. This can then be used to shut the laser diode off if a temperature maximum for the system is exceeded.