PULSED OUTPUT CURRENT & VOLTAGE SPECIFICATIONS

- Pulsed Output Current Range: 0 Amps ~ 4 Amps

- Adjustable Pulse Width Range: 0.5 nsec - 8 µsec

- Typical Minimum Pulse Duration: 1 ns

- Internal Pulse Generator Repetition Rate Range: 1 Hz to 250 MHz

- Typ. Rise/Fall Time: 0.5 / 1 / 0.5 ns (TO / Butterfly / VCSEL)

- Output Current CW (continuous) Mode: 0 Amps ~ 2 A

- Adjustable Output Voltage Maximum: 24 Volts

- Temporal Jitter (rms): < 8 ps

- Back-Facet Power Monitor Connector

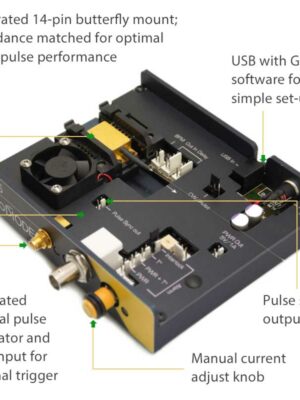

TEMPERATURE CONTROLLER & BUTTERFLY MOUNTING SOCKET

- TEC Current (max): 1.5 Amps

- TEC Voltage (max): 3.8 Volts

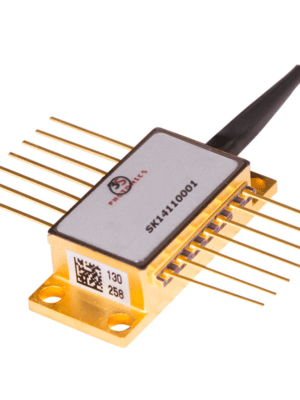

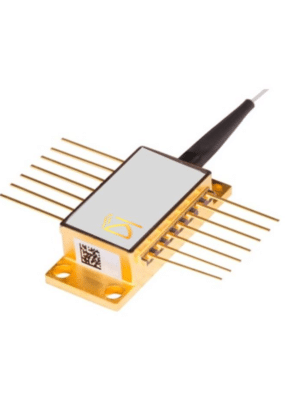

- Zero Insertion Force Mounting Socket for 14-Pin Butterfly

- TEC Controller Compatible with NTC Thermistors: 1 kΩ - 100 kΩ

- Laser Diode Temp. Range: 15 - 50°C

LASER DIODE PROTECTION

- User set Over-Current Limit Shut Down

- Over-Temperature Limit Shut Down

- Safety Interlock Shut-Down

- Soft-Start Ramp to Current Set-Point (CW mode)

- Transient and ESD Surge Protection

- Fast Error Detection and Shut Down Feedback

USER INTERFACE, POWER INPUT & DIMENSIONS (ALL MODELS)

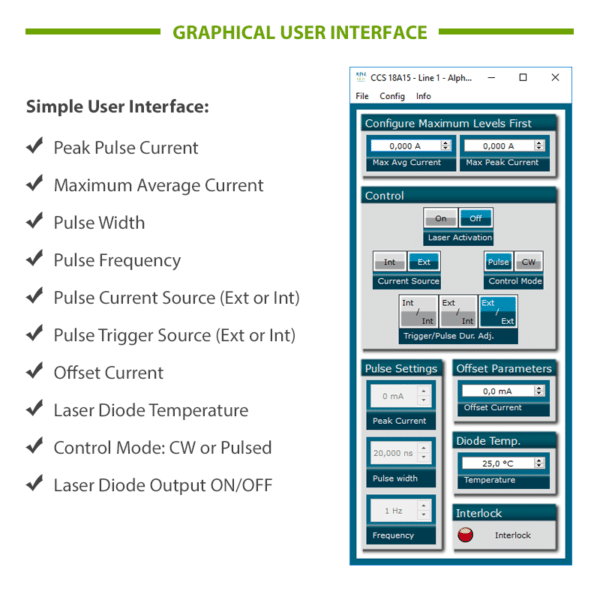

- Remote: USB with Control Software GUI

- DLL Library for C Programming and Hexadecimal Protocol are Available at No Charge

- Analog (0-3.3V) Remote Signal Peak Power Adjustment

- Input Power Supply: 12 VDC (220V / 110V Adapter Included)

- 170 mm (W) x 107 mm (L) x 27.5 mm(H)

PULSE GENERATION MECHANISMS ( 3 MODES )

- Internal Pulse Generator: On-board pulse generator

- External Trigger to Internal Pulse Generator: User supplied LVTTL signal triggers (on the rising edge) the internal generator to deliver the pulse. The pulse parameters are set in the internal pulse generator and the pulse is delivered from the internal generator.

- External Trigger Pulse Generator: Pulse duration is the same as the external trigger pulse duration

Pulsed Laser Diode Driver; 4 Amps / 24 Volts; Adjustable Pulses from 0.5 nsec to 8 µsec; 250 MHz, Integrated Butterfly Mount

Key Features

- User Set Pulse Widths from 0.5 ns to 8 µs

- 4 Amp Current Range; 24V Voltage Range

- 1 Hz to 250 MHz Repetition Rate

- Integrated Pre-Configured Butterfly Mounting Socket & TEC Temperature Controller

- 24V High Compliance Voltage

- USB Interface, Includes Programming Tools Software Suite, DLL Library and GUI

Shipping Information

Shipping within the USA: $155.00

International Shipments: Shipping Account Required

Offered by: AeroDIODE Corporation, a Laser Lab Source Marketplace Seller

Orders fulfilled by: Laser Lab Source in North America

Sold & Supported in North America by Laser Lab Source

Orders for this product are processed and fulfilled by Laser Lab Source, the marketplace for Laser Scientists and Engineers. This item ships from Bozeman, MT USA. It is manufactured by Aerodiode, a Laser Lab Source Marketplace Seller. Mfg Part Number: CCS-HPP

Warranty Information

This product is sold with a full one year warranty. It is warrantied to be free from defects in material and/or workmanship for a period of one year from the date of shipment. The warranty is transacted and honored by Laser Lab Source for product purchases made through Laser Lab Source.

|

Weight |

3 lbs |

|---|---|

|

Dimensions |

13 × 9 × 9 in |

|

Current Range |

1 Amp - 5 Amp |

|

Voltage Range |

10 Volts - 25 Volts |

|

Min. Pulse Width |

0.5 nsec |

|

Minimum Pulse Width Range |

100 psec - 999 psec |

|

Integrated Control and Mount Units |

Butterfly Units |

|

Form Factor |

Module (no front panel) |

|

Computer IO and Software |

GUI software included, Python Libraries, USB Available |

|

Drive Current Mode |

CW + QCW Mode |

|

Driver Current |

4 A |

|

Driver Voltage |

24 V |

|

Laser Diode Drivers |

PULSED Mode |

Product Overview

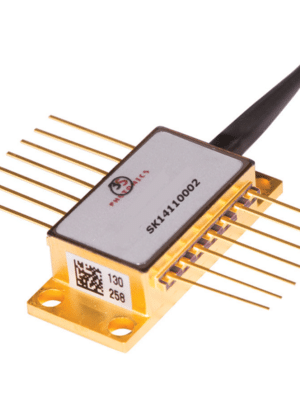

CCS-HPP High Pulse Performance Laser Diode Driver & Mount Unit

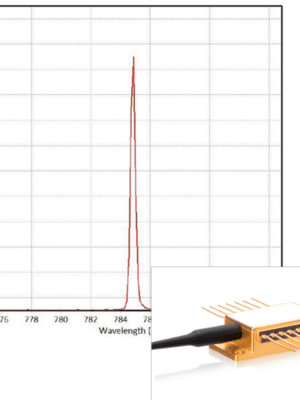

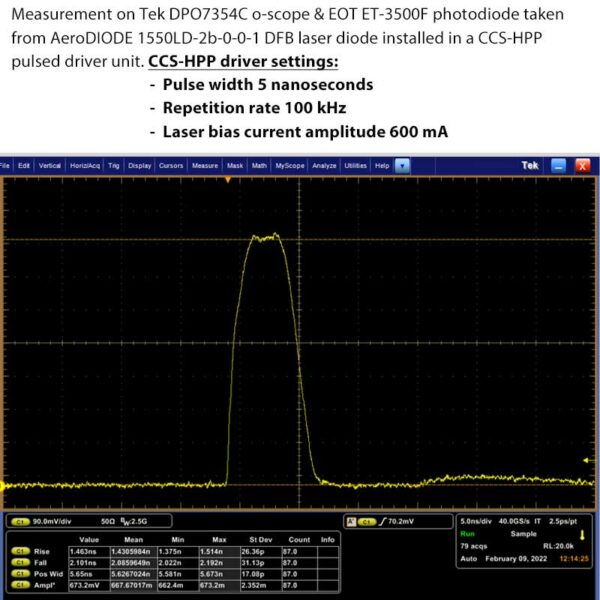

This pulsed laser diode driver and butterfly mounting module is optimized for high performance, high power pulsing with pulse width from 0.5 ns to 8 µs. These pulsed control and mounting modules deliver precision pulses which are generated internally by an on-board pulse generator, or on demand from your external TTL signal generator.

Laser Diode Protection Features

The CCS-HPP series drivers include comprehensive laser diode protection. They include an efficient TEC controller which keeps the laser temperature stable and protects it from thermal damage. The USB interface and graphical user interface offers the user complete control of the temperature and current limit parameters. The user controls pulse width, amplitude, rep. rate, temperature set point, current / temperature limits and more.

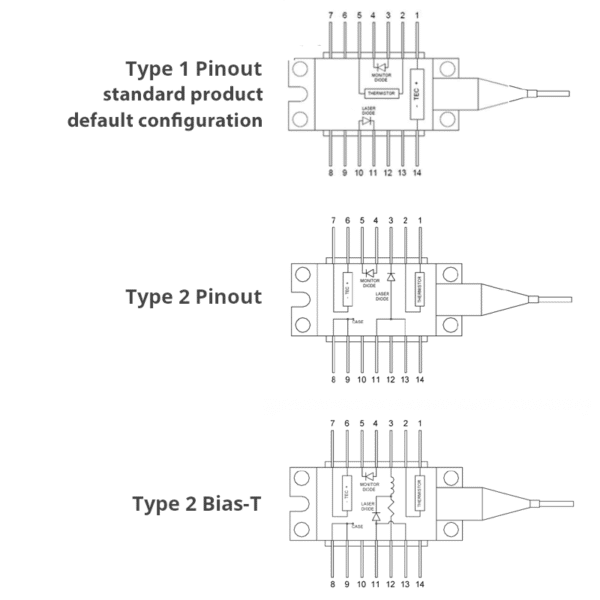

Pin Configurations

The CCS-HPP is available for industry-standard butterfly package pin configurations. Because impedance matching is a critical factor in delivering clean high speed pulse performance, the CCS-HPP unit is pre-set for your laser diode’s pin configuration (TYPE-1 by default). Refer to the images above to view available pin settings. The standard configuration is the Type-1 pinout; please inquire if you require the Type-2 pin configuration.

Flexible Pulse Generation and Output Synchronization

These drivers offer the user three different pulse generation sources. The internal pulse generator; an external trigger source; or an external trigger source can be used to activate the internal pulse generator.

When using an external trigger source, the input pulse trigger is a TTL/LVTTL input voltage. The input voltage range for the external trigger is 0 ~ 3.3 Volts. These units also provide the user with a sync-out port which allows synchronization of the driver to related test equipment. This SMA output port delivers an LVTTL copy of the CC-S logical driving signal.

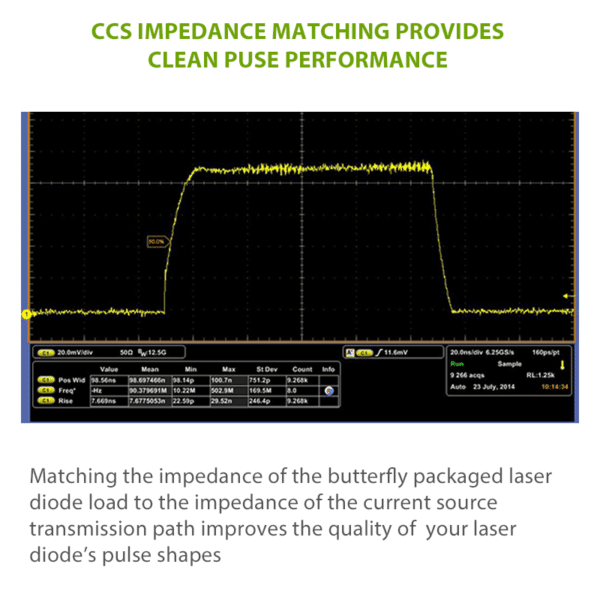

Pre-Set Impedance Matching Improves Laser Diode Pulse Performance

If the impedance from the pulsed current source PCB is not properly matched to the butterfly package pins pulse degradation can occur, and can hamper operating in the intended application. The degradation is sometimes seen as distortion or overshoot of the laser output pulses. The CCS pulse unit is designed to reduce and/or eliminate this pulse degradation by matching the nominal impedance of the butterfly packaged laser diode with the pulse transmission line.

Current sources inherently have a high output impedance and laser diodes have very low impedance. The most important requirement of proper impedance matching is matching the impedance of the load to the impedance of the transmission line. The inductance of laser diodes ranges from a few nanohenries to tens of nanohenries. From inductance theory, 𝑑𝑖/𝑑𝑡 is the rate of change in current over a specific period in amperes per second. The voltage increases with the inductance and with the rate of the change of the current. Energy stored in the inductor’s magnetic fields during the pulse has to be released when the pulse ends. This creates a voltage, which in turn creates a new current, which in turn creates a new magnetic field on the transmission path. This creates a “loop” which manifests as “ringing” on the pulse waveform and on other distortions to the pulse shape. The CCS current output transmission path has been carefully designed to match the current source impedance to the butterfly packaged laser diode.